Settings & Changeover

Settings & Changeover is an essential part of the production process; it defines machine settings and production material amounts to accurately manufacture a specific product in a consistent manner. Recipe software fits into the Manufacturing Execution System (MES) layer that resides between the Enterprise Resource Planning (ERP) layer and the plant floor. Settings & Changeover provides an efficient means to manage and select recipes, track variances in recipe values, keep recipes secure, track recipe changes, analyze recipes, generate recipe reports, and more!

Introduction to Settings & Changeover

Introduction to Settings & Changeover

Extend your MES system with the Sepasoft® Settings & Changeover Module to expertly build, manage, and monitor machine settings. This powerful module is ideal for quickly and accurately changing machine or process settings.

Some features of the Settings & Changeover Module include:

- Master recipe management

- Sub-recipe management

- Recipe security

- Changelog tracking

- Variance tracking

- And much more

This module greatly reduces the time usually required to manage production recipes and is a must-have in any industry that produces different products or runs machines in different modes.

Automation Software For Machine Settings

A recipe defines machine settings and amounts to manufacture a specific product in a consistent manner–an essential part of the production process. This software fits into the MES layer that resides between the ERP layer and the plant floor. Improve efficiency, quality, and production control of your manufacturing facility with powerful master recipe and sub-recipe management, recipe security, changelog tracking, variance tracking, and more.

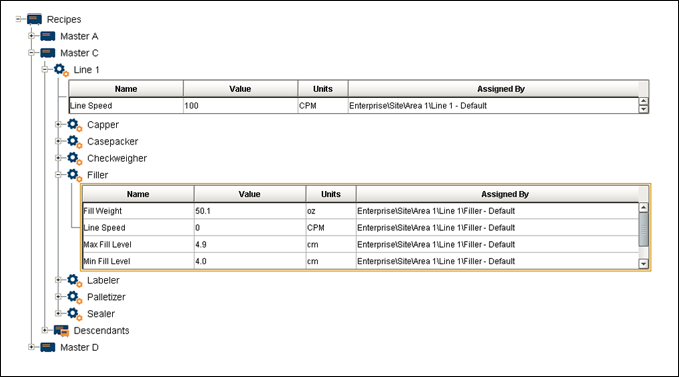

Master Recipe Management

Reduce the effort required to manage numerous recipes with master recipe functionality. When a master recipe setting is changed, it will replicate down to all of its sub-recipes while maintaining the specific values of each sub-recipe. With unlimited levels of master recipes, recipes can be organized in a hierarchical manner.

Simple Recipe Editing

Managing recipes has never been easier using the Settings & Changeover Module’s built-in visual recipe editor. The following editing capabilities are now just a mouse-click away:

Complete Recipe Scripting

Meet the unique requirements of your organization rather than altering your production environment due to software limitations. For custom functionality beyond the Settings & Changeover Module’s out-of-box features, utilize complete scripting functions to:

OEE, SPC, and Trace Integration

In a production process that fully employs the Sepasoft® MES Suite of modules, making a single product code selection sets recipe values, starts overall equipment effectiveness (OEE) tracking, collects statistical process control (SPC) samples, and provides complete production traceability. During and after the production run, the Sepasoft® Settings & Changeover Module enables analysis of the following data in one unified system:

- Recipe data

- Production data

- SPC data

- Track & Trace data

- And more

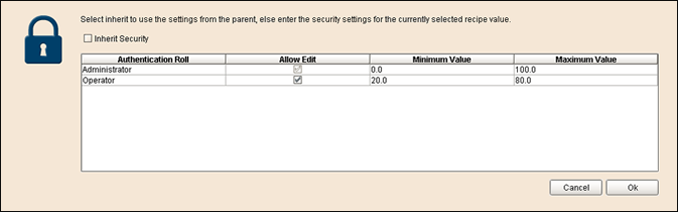

Track & Secure Recipes

Limit deviations from standard machine settings by utilizing role-based security to define user roles and permissions. The Settings & Changeover Module allows you to:

Detailed Changelog

All changes made to any recipe are automatically recorded in the Settings & Changeover detailed changelog to help you meet the challenges of regulatory compliance. Quickly zero in on significant changes with access to a complete audit trail evidencing:

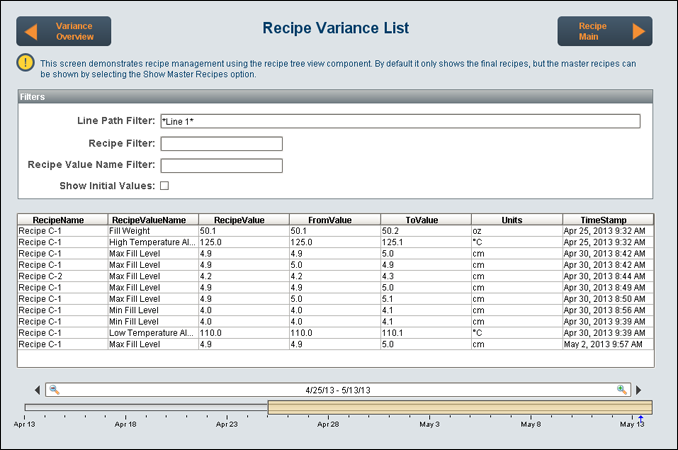

Monitor Recipes In Real-Time

Monitor machine settings and identify deviations in real-time to prevent quality, downtime, or other production issues. Machine settings changed at an operator interface terminal outside of the recipe management system are detailed in the Settings & Changeover Variance Log.

The Sepasoft® Settings & Changeover Module Variance Log enables users to detect variances in real-time or to review variances by production run or date range. These capabilities make it possible to identify the root causes of production issues as early as possible.

The Variance Log also allows limit definitions for which variances to record. The following types of thresholds can be defined by recipe value:

Analyze Recipes

Identify trends and carry forward successful practices to future operations by analyzing unlimited amounts of past production data. Use our Settings & Changeover Module’s built-in analysis tools to:

- Compare recipes

- Review recipe change logs

- Review production-run variances

- And more

Reliably communicate results across the organization by integrating with the Ignition® Reporting Module to automatically generate and send reports via email or other methods.

Enterprise Integration

The Settings & Changeover Module is IT-friendly, allowing integration with enterprise resource planning (ERP) and other applications to share data and communicate seamlessly with the entire organization. With the ability to synchronize data and monitor system health across sites and servers, the Settings & Changeover Module improves visibility across the enterprise and supports organizational growth over time.

To learn more or to purchase the Settings & Changeover Module, contact Sales at 800-207-5506, select Option 1, or visit our pricing page