14 Steps for a Successful MES Implementation

14 Steps for a Successful MES Implementation

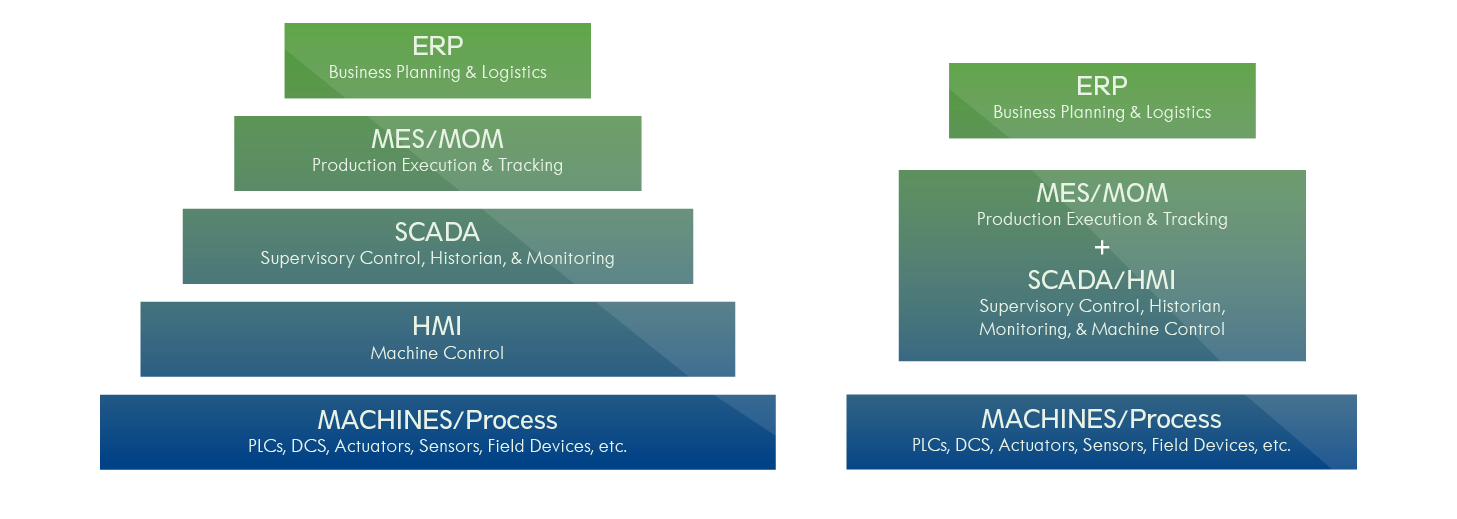

Manufacturing Execution System (MES) implementations bridge higher-level planning systems with plant floor control systems. Typically, this system will involve many departments and personas, in addition to accommodating existing processes. The end result makes MES one of the most challenging systems to successfully implement. Even companies that are ultimately successful must overcome many challenges along the way, both technical and non-technical in nature. So what can you do now to prepare for these upcoming hurdles? How can you avoid the red flags that often correlate with project failure?

Here is a list of 14 steps to consider when implementing an MES system. By researching best practices and common pitfalls now, you will be better prepared to dive into your own MES project.

1. Recognize the Need

The truth is, all companies have an MES system. It may be a completely manual process based on paper or spreadsheets. It may be a company with partial or legacy systems that are limping along just enough to keep the company running. Some companies may be so small that all MES-related details can be tracked in a single person’s mind. There is absolutely nothing wrong with these systems. However, the fact that you are reading this post reveals there is room for improvement of your current MES process. If you are pitching the need to upgrade your MES system, identifying the key issues that cause production inefficiencies is a critical first step. For example, are your orders filled late? Is overtime required to meet commitments? Do you need to increase capacity? Solidify your understanding of where the most fundamental issues lie before selling the need to others.

2. Sell the Need

You may not think of yourself as a salesperson, but this step must happen in order to achieve a successful MES implementation. Whether early on, or later in the implementation process, everyone will eventually need to be sold on the need for MES. Without question, there will be naysayers and those who are averse to change. After all, transitioning to a formal MES is full of unknowns, especially for production staff who may not see the high-level need as clearly.

To help bridge the gap, every team needs a “Project Champion”, the internal salesperson who is responsible for pushing the project forward and advocating when it meets resistance. Oscar Salcedo, a Sepasoft customer at Samtec explained, “The main thing for us was having that internal champion that would follow through on a day-to-day basis on making sure that the data was accurate, that the operators were using the system as they should and communicating any potential issues to us so we can resolve them. You gain mindshare, you gain trust from the lowest level on the floor, and that was a huge, huge benefit for us.”

3. Find an Executive Sponsor

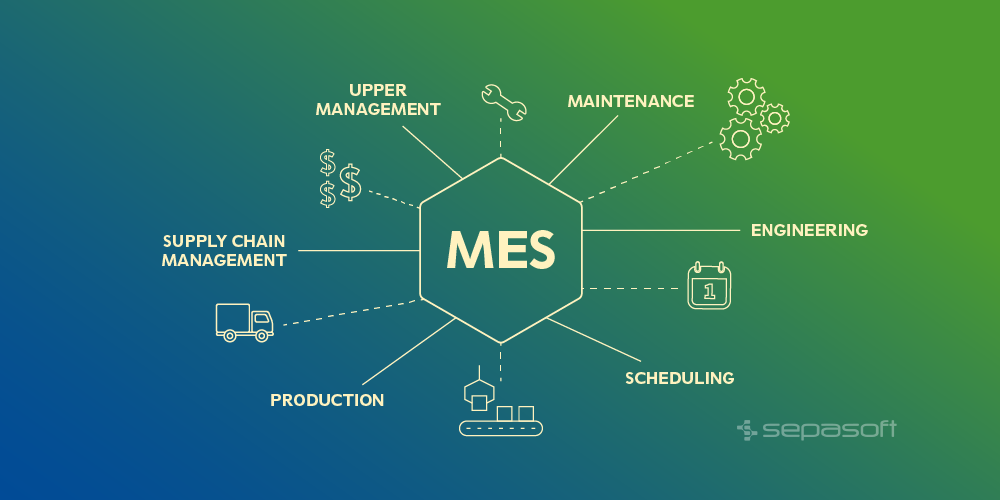

Behavioral change is complex, but successfully implementing a MES requires convincing those resistant to change to step outside their comfort zone. Gaining buy-in from an Executive Sponsor in upper management provides some valuable forward momentum in this area.

The Executive Sponsor is responsible for communicating project goals and gathering support from senior executives. This also means advocating for your project to overcome resistance from other senior executives. Getting upper management on board is not only integral for funding approval, but sets an example for other departments.

4. Define the Scope

It is vital to consider each persona, research the problems or challenges each persona is experiencing, and build an MES system with the right functionality to help solve these problems. Including functionality that benefits many personas is more likely to result in overall ownership of the MES system. That is, more departments will have something to gain if the project is a success.

The larger an implementation is in scope, the more important it is to break the project up into phases. Each phase should include who the customer is, the problems that need to be solved, boundaries, and the success criteria. If you are an integrator reading this, a customer does not necessarily mean the company that you have a contract with. The customer is whoever uses or interacts with the MES system. Examples include: line operators, shift supervisors, and upper management.

5. Infrastructure

The ideal MES system can write data to, and read data from, machine controllers to minimize the manual tasks an operator must perform. In truth, any manual system that does not automatically collect data will be less accurate due to data entry error. For example, when equipment goes down, the first priority for the operator is resolving the cause and resuming production. When the line is running again, only then can the operator record the downtime event and estimate the duration. On the other hand, an automated system can track the downtime event down to the second. The operator can always add more contextual details that will be helpful when closing the loop and improving efficiency.

An infrastructure audit should be conducted prior to writing the scope so that any required changes are factored into the project funding request. If you are implementing an MES system in a plant that has been around for awhile, communications to the machine controllers may not exist. In some cases, this may require replacing controllers because they don’t have communications features. Next, the network must be present at each machine controller. In addition to PLC and plant floor device connectivity, you may also need to purchase and install operator terminals, barcode scanners, and overhead displays.

Depending on the interaction with production, servers may need to be on-premise or you run the risk of stopped production during WAN interruptions. For example, if the production rate is high and a 500mS delay will cause a brief pause on a machine while it waits for a response to verify the selected lot, then an on-premise server of some sort is needed. Likewise, if there is an extended WAN interruption and loss of production cannot be tolerated, then an on-premise server is needed. In the future, WAN connections will likely become more reliable and on-premise servers will not be required. In the meantime, an on-premise or hybrid architecture is recommended.

The hybrid solution involves a smaller server that only maintains a limited window of future and past production data. The complete production data is maintained in the cloud or in a private data center. The hybrid solution also helps reduce ongoing cost to maintain backup or redundant databases, backups, etc. because the on-premise server can be restored from the cloud servers.

6. So Many Choices

There are a variety of MES systems ranging from canned for specific industries, to configurable for any industry. Before committing to an option, it is crucial to document some basic requirements first. These do not need to be full MES system requirements, but they should provide enough information to vendors to fulfill your basic MES requirements.

For example, your basic MES requirements should include production rates, estimated counts of resources like material items, disaster recovery requirements, level of service, handling of WAN outages, etc. Try to keep the list as concise and relevant as possible. Avoid vague requirements like “must support reporting”; all systems likely support reporting, so this requirement will not help narrow down the best option for your company.

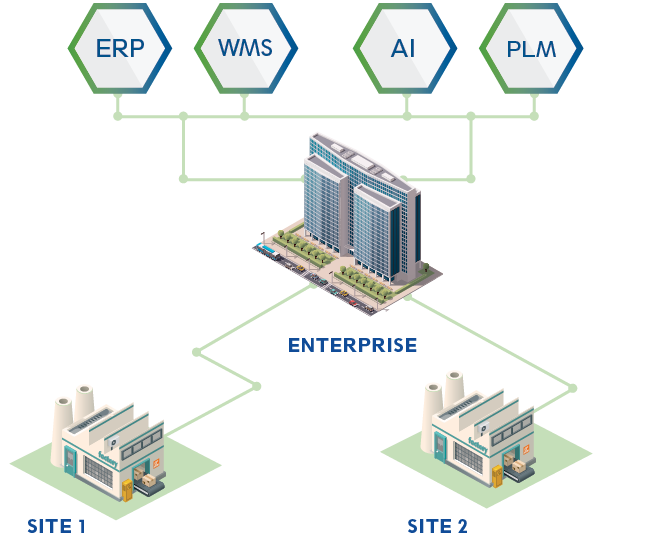

A major requirement to consider is how your MES will integrate with other systems such as Enterprise Resources Planning (ERP), Human-Machine Interface (HMI), Supervisory Control and Data Acquisition (SCADA), and others.

The more custom integration that is necessary to connect everything, the more complex and labor-intensive the implementation will be. This means more development labor and longer rollout timeframe, not to mention the need to dedicate more ongoing resources to maintain the system and custom integration in the future. For these reasons, integrations should be researched thoroughly and early in the selection process.

7. Funding

After an MES implementation, every company discovers benefits they never expected at the start of their implementation. For example, by successfully implementing a formal OEE solution, a major chemical manufacturer was able to reduce its workweek from seven days to five days, resulting in both significant financial savings and increased employee morale. If an MES solution is implemented correctly, there will undoubtedly be savings. But the real question is, “Will there be enough savings to pay for the project?”

Determining the ROI for MES systems is challenging when a hypothetical return is hard to estimate. Answering subjective questions like “how much can production staff be reduced,” “how much quality will be increased,” and “how much will efficiency increase” is difficult without historical data. If a funding approval depends on a project’s ROI, how should you proceed?

The best approach to determining pre-implementation ROI is to look for inefficiencies such as reworked/scrapped product or production interruptions caused by lack of coordination. There is a very high probability that inefficiencies like these can be resolved by installing an MES system, so an ROI can be calculated in advance.

Once you have rolled out the first facility or area within a facility, closely monitor and record the KPIs to help calculate ROI on future rollouts. This will likely include the improvements that were not expected at the beginning of the project.

8. Procurement

The procurement process involves the terms between the end customer, vendors, and any integration companies. It also involves pricing and legal negotiations that may cause potential delays in the MES implementation. A recommendation for this step is to start the procurement process early, even before the final MES software vendor is chosen. Overlapping this step with prior steps will save time.

When fielding a solution for your MES project, consider not only the initial purchase price, but any ongoing costs and labor required to expand scope and maintain the system. This is defined as the Total Cost of Ownership (TCO), and includes all ongoing costs, including support renewals, service subscriptions, operator terminals, number of required servers, etc. By conducting an upfront cost analysis, the goal is to minimize unforeseen surprises down the road. Low initial costs look great unless they are accompanied by hidden fees years later.

9. Project Management

Far too often, MES implementation may fall in the hands of a single engineer or department. Sometimes this works out; however, without proper training, an engineer may overcomplicate the implementation or fail to use techniques that can be easily rolled out. This may result in project delays and a system that is difficult to maintain after the initial MES implementation is complete.

Because MES implementations involve many departments, the need for a Project Manager that handles the coordination between all of the different entities is crucial. The Project Manager monitors the implementation progress and ensures all disciplines are progressing smoothly. If any discipline is not progressing smoothly, the Project Manager aims to bring the project back on track by whatever means necessary. Without this role filled, the risk of delay or failure greatly increases.

Although not always the case, it is fairly common that IT and OT are not the best of buddies. The two must be coordinated when implementing an MES solution because data is passed back and forth between the ERP, or other business systems, and the MES layer. Also, IT is usually responsible for managing the servers running the MES software. If the two departments are like oil and water, then the Project Manager is the mediator to help keep both IT and OT progressing forward.

10. Will it Work?

This step is often skipped, but is very important to achieving success. Any time operators, supervisors, management, maintenance, and others experience incorrect data or bugs, the credibility of the MES system is diminished. Negative experiences can even reinforce the naysayers who were opposed in the very beginning.

The most important method to keep credibility high is to fully test the MES system with team members who are not part of the MES implementation team. This can be done using the live system during production, but use caution when turning it over to production staff until all counters, mode, states, KPIs, reports, routes, etc. have been fully tested.

11. Training

Training is commonly overlooked, but has a significant impact on the overall success of an MES implementation. Operators need to be prepared to quickly handle the various production issues that may arise. Otherwise, a system that was installed to increase efficiency may accomplish just the opposite. It is wise to include operator training in advance of startup, but not until after the user interface is stable.

Training the maintenance staff on basic operation, architectures, and data flows is encouraged. When PLCs are changed by someone who doesn’t understand the potential impacts on the MES system, or who doesn’t understand how to handle unexpected conditions in data flow, this will ultimately reduce efficiency.

Other departments that may need training include IT, quality, management, and scheduling staff. Identify those that will be using or supporting the MES system and proactively educate them prior to going live.

Training is an excellent time to pre-test the MES system. Usually, if something was overlooked or not working correctly, it will surface during training. It is also a good time to see how people interact with the MES system to make useability improvements.

12. Pilot

Pilots are generally not crucial unless you fall into a high-risk category. In these riskier scenarios, a pilot is highly recommended to avoid risking both credibility and finances. If a project is technically challenging or hasn’t been done before, then a proof of concept is critical. In other words, testing a theory is wise prior to gambling on that theory.

If a project doesn’t fit into the culture of your company, then use a pilot to test if the behavior change is achievable. This is also an opportunity to be agile and improve your solution to better fit your processes and company culture. If you position the test as an open pilot where ideas are welcome, then most contributors will be focused on what will help make operations run smoother. It is much less risky to consider new ideas at this stage versus after a large investment and substantial development have already been dedicated to a project.

Pilots are also valuable in collecting ROI data. The only way to accurately estimate what you can expect for your ROI is by doing a pilot. Again, this is an opportunity to use an agile approach to learn what will fit well within the company and provide the greatest returns.

13. Are We Done Yet?

An MES system will bring visibility to your inefficiencies and help determine the most important areas to focus improvement efforts. However, software and hardware alone cannot change a workflow, fix a chronic machine fault, train an operator, or reduce rework and waste. To be successful, teams should be organized to evaluate the data from the MES system and turn it into actions that will result in more efficiency. A full MES solution requires technical systems, training, analysis, new procedures, behavior change, and more.

To implement an MES system is not enough…you have to live and breathe MES day in and day out. Initially, a large amount of effort is required to establish workflows and train staff. As more employees are trained, more momentum is gained, resulting in a greater return.

Chances are your company is changing constantly, and as a result, your MES systems will be in constant flux as well. New products are added, machines are changed or moved, and new initiatives are implemented that all affect the MES solution. Plan for these business changes from the start in order to better accommodate them.

14. Rollout

The rollout phase can determine the success or failure of an MES implementation. Depending on the quantity and size of your production facilities, the time required to roll out MES to each facility will have a major impact on the implementation’s success as a whole. If your company has only 5 production facilities, then taking 6 months to roll out to each facility likely won’t make or break the MES enterprise implementation. However, if you have 25 manufacturing facilities and each takes 6 months, then it will take over 12 years to roll out your MES implementation. In the latter scenario especially, it is imperative to reduce rollout timing per manufacturing facility by considering common pitfalls and planning ahead.

Some common items that increase rollout time include hard coding, funding, over-complications, and scope creep to accommodate each facility’s desires. The term hard coding represents a structure that requires a lot of manual code changes for each manufacturing facility. Wherever possible, aim to streamline configuration of a system to the equipment model of each manufacturing facility using low-code approaches by taking advantage of UDTs (User-Defined Types), templates, parameters, standards, etc. This becomes even more important when rolling out updates after the initial rollout – less manual code means less maintenance labor over the life of the software.

Instead of including every feature on your wish list in the initial rollout, start with an MVP (Minimum Viable Product), and roll out updates and new features over time. Whenever possible, utilize built-in functionality and ready-made components rather than complex custom solutions. Although everyone’s needs are unique, taking advantage of out-of-the-box functionality allows for a quicker rollout. Start small and avoid over-complications – you will learn so much after the first facility and this valuable insight can then be applied to future rollouts. By aiming for an MVP and keeping it simple, you can learn from early experiences and THEN customize to enhance your MES solution. Taking this approach will greatly reduce scope creep and reduce the risk of a failed rollout.

How Can Sepasoft Help You?

The 14 steps discussed above are common themes we’ve seen time and time again throughout countless MES implementations. At Sepasoft, a top initiative is to arm customers and integrators with the tools needed to carry out a successful project. Here are a few of the resources Sepasoft offers to provide gap analysis, architecture reviews, project reviews, best practices, and more during the implementation process:

- Free consultation time with MES Design Engineers for Sepasoft customers

- Directory of qualified third-party system integrators that have successfully completed Sepasoft’s MES Certified Integrator Program

- Free help documentation and training videos on the Sepasoft website

To learn what Sepasoft MES can do for your organization, please schedule a demo.