Explore how Sepasoft MES and Inductive Automation’s Ignition platform enhance manufacturing with seamless integration, scalability, and real-time data insights.

Are siloed systems crippling your factory’s potential? Operational excellence in modern manufacturing demands seamless software integration. Imagine: no more wrestling with fragmented data, cumbersome custom bridges, or scalability issues.

That’s the vision behind the partnership between Sepasoft and Inductive Automation. Among manufacturing software providers, they stand out by combining the power of Manufacturing Execution Systems (MES) and Supervisory Control and Data Acquisition (SCADA) platforms into a unified solution. This partnership not only enhances functionality but also provides unparalleled value to customers seeking efficient, scalable, and innovative manufacturing solutions.

The Backbone: Inductive Automation’s Ignition Platform

At the core of this integration is Inductive Automation’s Ignition platform. Ignition is a robust, versatile SCADA platform that provides tools for data acquisition, control, and analysis across various industrial processes. Known for its flexibility and scalability, Ignition empowers businesses to connect disparate systems, visualize real-time data, and streamline operations.

Ignition’s unlimited licensing model supports unlimited tags, clients, devices, and connections at no additional cost, making it an ideal foundation for complex industrial environments. Its modular design allows users to customize and expand functionalities based on specific needs, ensuring a tailored solution for every application.

“Sepasoft’s modules slot right into Ignition, expediting MES development while delivering a powerful feature set including batch processing, downtime monitoring, procedure management, and more.”

Enhancing Capabilities: Sepasoft’s MES Modules

While Ignition is ideal for SCADA and HMI applications, it doesn’t have native capabilities required for comprehensive MES operations. Consequently, any MES functionality must either be integrated from an existing solution or developed, defined, and tested from scratch. Sepasoft extends Ignition’s capabilities with MES modules designed to control, trace, and document the transformation of raw materials into finished goods in real-time.

Building on the solid foundation of Ignition, Sepasoft offers an extensive suite of MES tools and prebuilt components to streamline manufacturing operations, ensure consistency, and enhance productivity. The suite includes solutions for workflow management, traceability, statistical quality control, overall equipment effectiveness (OEE), document management, connection with other business systems like SAP ERP, and more. These tools empower manufacturers to leverage real-time data for informed decision-making and continuous improvement.

KEY FEATURES & BENEFITS

1. Enhanced Functionality:

Sepasoft MES offers robust functionality that would be time-consuming and costly to develop from scratch. Over a decade of development and fine-tuning, combined with customer collaboration across various industries, has resulted in a refined product that embodies best practices and continuous improvements. This partnership with Inductive Automation allows Ignition users to leverage Sepasoft’s expertise and specialized modules for a complete MES solution without the complexities and risks associated with custom development.

2. Unified Operator Interface:

Operators can access all necessary tools and information from a single interface, minimizing the learning curve and allowing users to quickly adapt to one system. This unified interface consolidates data for a comprehensive view of manufacturing operations, helping operators to understand how their actions impact the overall process and make better-informed decisions.

3. Scalability:

Ignition and Sepasoft are designed with scalability in mind, both in size and scope. Whether a business operates a single facility or manages a global network of plants, the combined solution can scale to meet growing demands without sacrificing performance. With modular architectures, Ignition and Sepasoft MES enable companies to easily adapt to changing project needs and technologies.

4. Joint Solution:

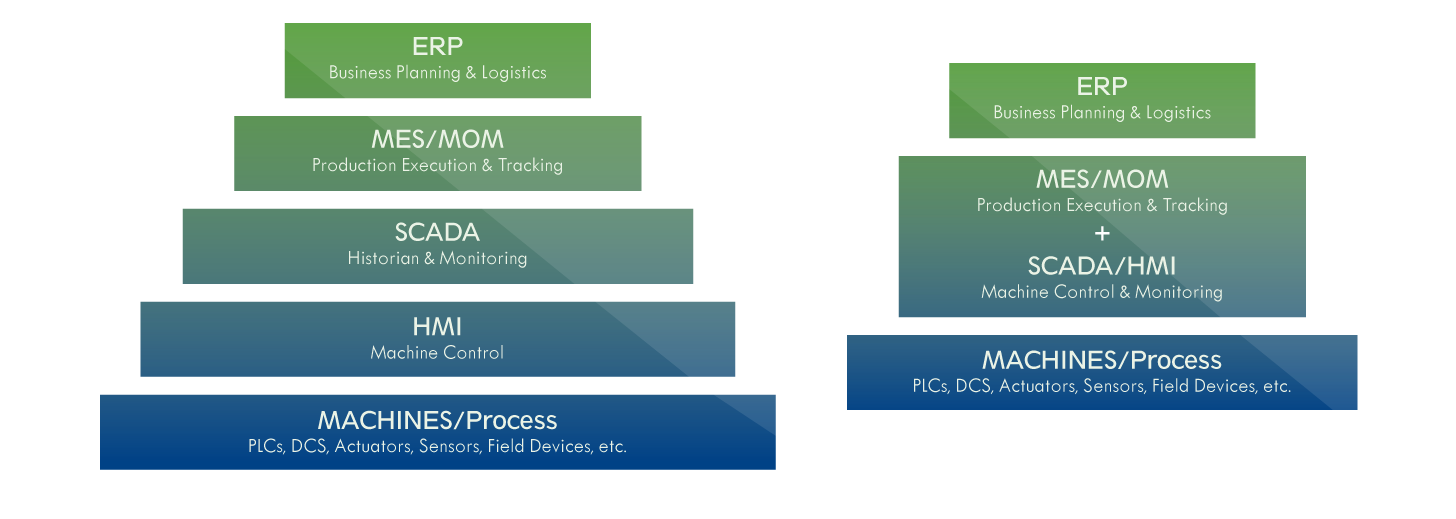

Traditionally, HMI, SCADA, and MES have been seen as distinct software levels in the manufacturing business hierarchy. “Flattening the stack” reduces the need for intermediary layers or custom integrations, resulting in a software stack that is more scalable and easier to maintain. With natively integrated software, development time is reduced, leading to a quicker MES deployment.

“One of the best ways to implement an MES solution is to use the Ignition software platform with Sepasoft’s suite of MES modules.”

‘Flatten the Stack’ with Sepasoft MES & Ignition

Sepasoft is an official Inductive Automation Solution Partner. The Inductive Automation Solution Partner Program “showcases hardware, software, and service providers who offer solutions and technologies that are powered by Inductive Automation’s Ignition® software”. According to Inductive Automation, the benefits of working with a Solution Partner include:

● Seamless compatibility with Ignition software

● Years of industry expertise within their domain

● Provide valuable support for their solutions

● Trusted by Inductive Automation

This partnership underscores Sepasoft’s expertise and reliability in delivering top-tier MES software that effortlessly integrates with Ignition. Customers can have confidence in the combined solution, knowing that it is backed by a trusted partnership.

A Natural Fit

The seamless integration of Sepasoft and Ignition is not coincidental. Shortly after Steve Hechtman set out to develop a world-class SCADA platform in Ignition, Tom Hechtman founded Sepasoft to build MES software that naturally complements Ignition. With headquarters just a few miles from each other, the two companies have grown and succeeded by building powerful, user-friendly manufacturing solutions that cohesively work together. For a deeper dive into what MES can do and how Sepasoft’s solutions fit seamlessly with Ignition, check out Inductive Automation’s article “What is MES?”.

Contact Sepasoft

Want to see the impact for yourself? Request your Live Free Demo of Sepasoft today, or contact us to learn more about what the combined power of Sepasoft and Inductive Automation can do for your operation.