Understanding Starved and Blocked Equipment States

Uncovering Manufacturing Opportunities: Understanding Starved and Blocked Equipment States

In manufacturing, every minute matters. When production halts or decelerates, profitability is directly impacted. Frequently, these slowdowns are caused by particular equipment states known as “starved” and “blocked.”

In a starved state, machinery waits idly for materials from upstream processes, unable to continue its operation. On the other hand, a blocked state signifies a machine ready — but obstructed — to pass materials downstream due to a lag in the subsequent process. These instances of inefficiency disrupt the smooth flow of the production process. The silver lining is that they represent opportunities for optimization and productivity improvement.

What is Starved and Blocked Analysis?

First of all, let’s define the key concept in a little more detail. In the context of manufacturing, starved and blocked analysis is an effective tool used to spotlight and measure periods when equipment is either “starved” or “blocked.”

In simpler terms, this analysis pinpoints instances when equipment is awaiting materials from a preceding process (starved) or unable to transfer materials to the next process (blocked). This meticulous examination assists manufacturers in highlighting inefficiencies in their workflow. It enables them to better comprehend their processes and equips them with invaluable insights that can lead to significant process improvement.

1. Utilizing OEE as a Measure of Equipment Effectiveness

A universally recognized and frequently utilized metric in manufacturing is Overall Equipment Effectiveness (OEE). This KPI provides critical insights into the utilization of equipment and processes. By carefully assessing availability (whether the process is running), performance (speed at which the process is running), and quality (number of defects in the output), OEE provides a holistic and nuanced view of productivity. However, to truly harness the power of this metric and gain a profound understanding of your manufacturing process, it’s vital to look deeper into the underlying causes of any detected inefficiencies.

2. Identifying Hidden Causes of Lost Time

Downtime can be a significant cost factor for any manufacturer. To unearth concealed cost and productivity thieves contributing to downtime, a comprehensive examination of the operation as a whole is a necessity, which includes a starved and blocked analysis. Through this, manufacturers can identify systemic issues and create targeted strategies for process improvement.

3. Leveraging Starved and Blocked Analysis

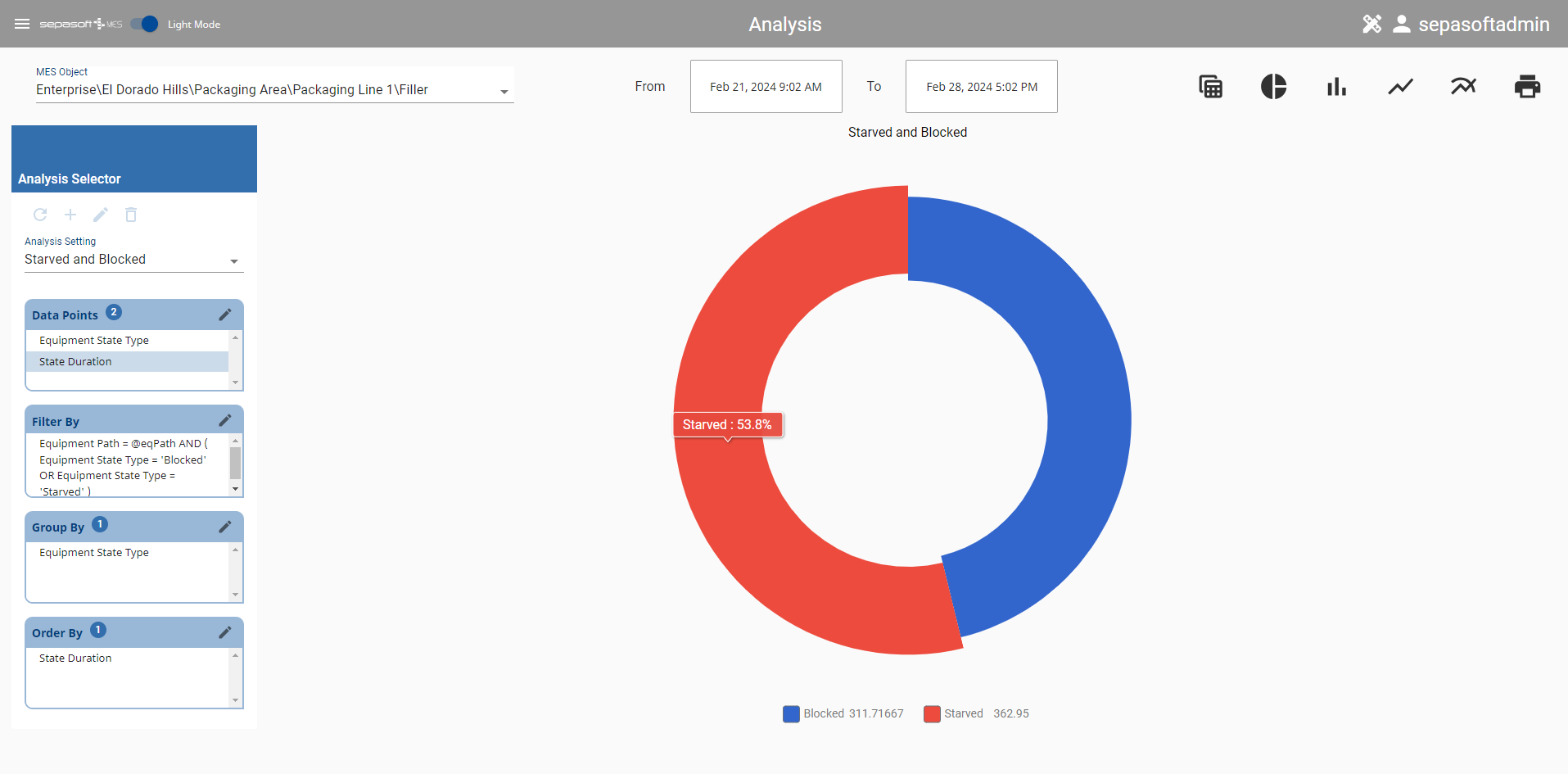

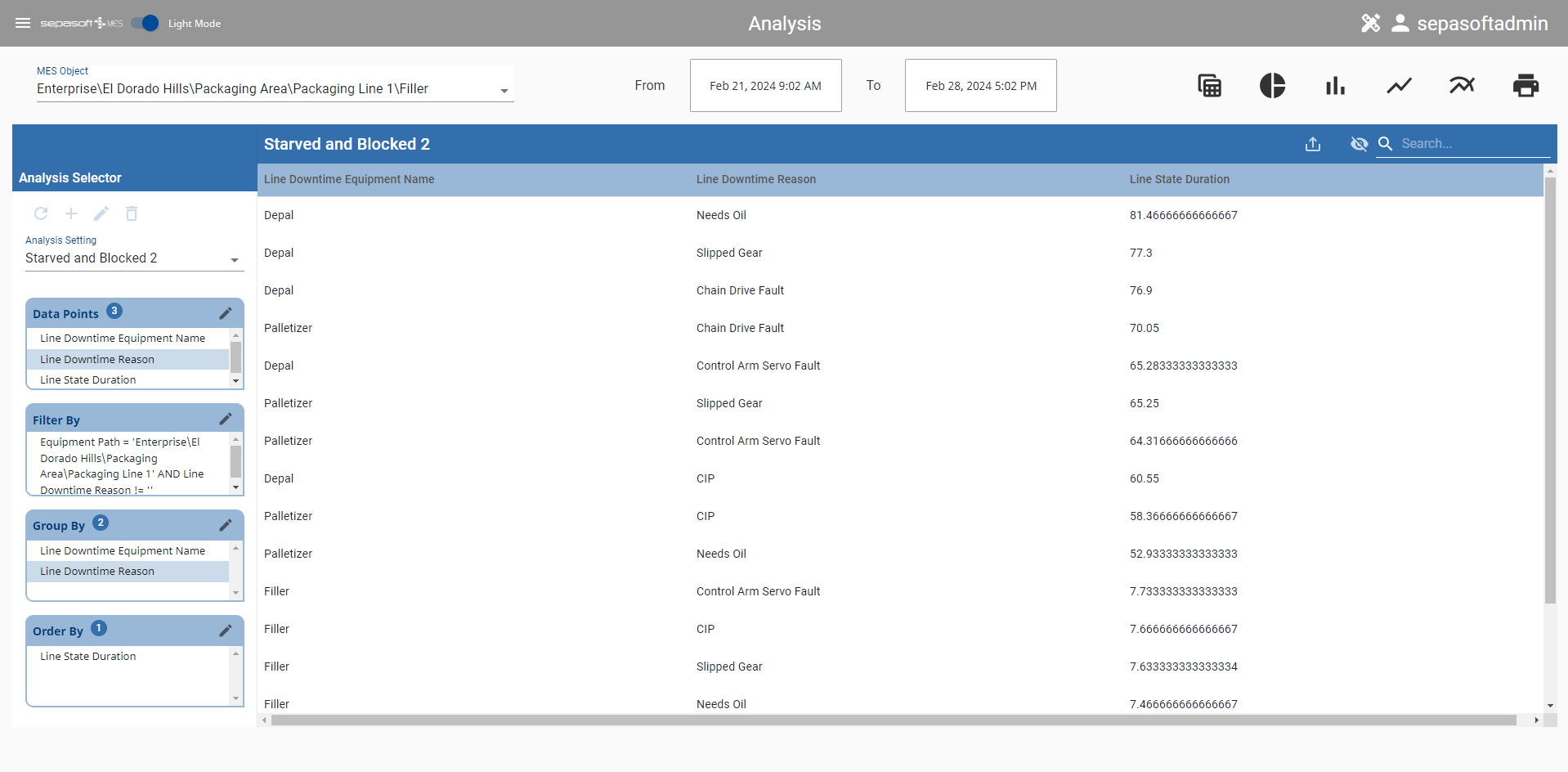

Starved and blocked analysis offers a unique perspective on what is contributing to downtime. By identifying periods when equipment is starved or blocked, manufacturers can find specific areas where workflow and coordination can be improved. A good starved and blocked analysis should be able to help identify the root cause for downtime such as those shown here.

Common Starved Causes:

- Insufficient Input Materials: Shortages or delays in the supply of raw materials can lead to a blocked production line. If a workstation is waiting for materials to arrive, it is starved; if it cannot operate at its full capacity.

- Machine Breakdowns: If a critical machine or equipment required for a specific production task breaks down, it can cause a bottleneck, leading to other stages being starved of work.

- Labor Shortages: Inadequate manpower to operate a particular workstation can result in a starved production line. This could be due to absenteeism, turnover, or insufficient workforce planning.

- Tooling or Fixture Issues: Problems with specialized tools or fixtures required for a production stage can lead to a starved condition if they are damaged, malfunctioning, or unavailable.

- Quality Control Delays: Delays in the quality control process, where products need to be inspected before moving to the next stage, can cause a backlog and starve downstream production stages.

- Engineering Changeovers: Frequent engineering changeovers or adjustments in the production line can lead to downtime for certain workstations, causing a starved effect.

Common Blocked Causes:

- Equipment Failures: Malfunctions, breakdowns, or failures of machinery and equipment can cause a workstation to be blocked, preventing the movement of products to the next stage.

- Quality Issues: If there are defects or quality issues identified during the production process, products may be held back, blocking the production line until the issues are addressed.

- Overproduction: Producing more units than the downstream stages can handle can lead to a blocked production line as excess products accumulate and create a backlog.

- Supply Chain Disruptions: Disruptions in the supply chain, such as delayed shipments or shortages, can block the production line if the necessary components or materials are not available.

- Changeover Delays: Delays in transitioning from one product or production run to another (changeovers) can lead to a blocked production line until the necessary adjustments are made.

- Environmental Factors: Adverse weather conditions or other environmental factors can impact production machinery, causing a blockage until issues are resolved.

Done properly, a starved and blocked analysis can expose recurring patterns, emerging trends, and persistent bottlenecks that may otherwise remain hidden. In essence, it provides a valuable tool for enhancing manufacturing efficiency and reducing waste.

4. Harnessing the Power of OEE Downtime

OEE (overall equipment effectiveness) indicates the value of starved and blocked analyses through the OEE Availability factor. It serves as a KPI and diagnostic, collecting essential data such as the total duration of starved and blocked states, the frequency of these events, and their correlation with other relevant information like product code, work order, or customer-configured data.

With the wealth of data and in-depth analysis offered by OEE tools, manufacturers are granted a deeper understanding of their production process. This information is instrumental in identifying potential areas for improvement and formulating effective strategies for process optimization.

The outcome? An increase in production capacity without the need for substantial capital investments. Thus, starved and blocked analyses prove to be an efficient and cost-effective method to maximize the utilization of existing resources.

Final Word

Understanding the dynamics of starved and blocked states in equipment represents a substantial opportunity for manufacturers. The dedicated analysis of these states and the circumstances leading to them can help manufacturers unearth hidden productivity potential within their operations, ultimately driving efficiency and profitability. By actively seeking out and addressing these issues, manufacturers can turn hidden challenges into visible opportunities for growth and success.

Are you ready to unlock your hidden productivity? Start your journey of process improvement and efficiency with Sepasoft. With our OEE Downtime solution, we can help you analyze and understand your starved and blocked states, streamline your workflow, and increase your manufacturing productivity. Don’t let inefficiencies slow you down. Contact Sepasoft today or request your free live demo. Let’s optimize your manufacturing processes together.