TOP 3 ERP VS. MES DIFFERENCES | PART 1

Enterprise Resource Planning (ERP) vendors often advertise features provided by Manufacturing Execution Systems (MES), so we must ask, which system is best suited to the task? What is best for my organization?

Before we determine a solution path, we should consider the differences between ERP and MES and weigh their strengths and weaknesses. These considerations are classified under three categories: Time Scale, Context, and Cost. In this post, we will explore Time Scale differences when choosing to field ERP or MES functionality for your critical manufacturing IT project.

- Time Scale

- Context

- Total Cost of Ownership (TCO)

Part 1: Time Scale

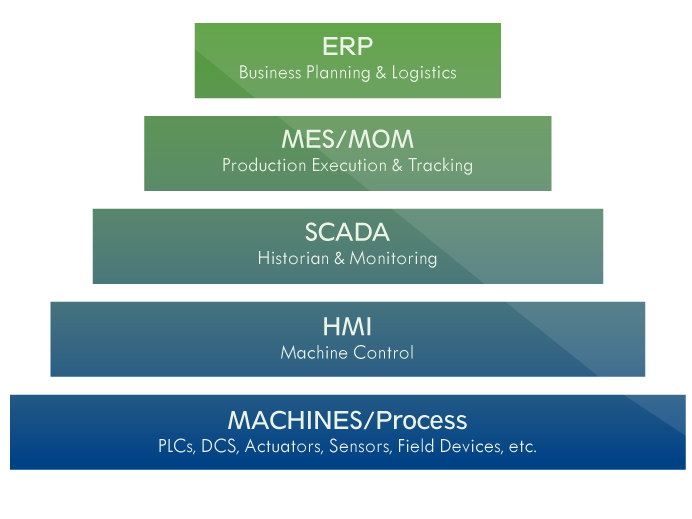

The systems in a manufacturing environment extend from the factory floor to the c-suite. There are large gaps between these systems in their respective purpose, functionality, and speed. Consider this: On the plant floor, automation systems operate at a milli-second time scale. Sensors and Programmable Logic Controllers (PLCs) must have near-instantaneous response times to control physical processes. Meanwhile, resource and sales numbers are often calculated on daily or monthly bases. Clearly, there is a considerable difference between these two systems.

While the control and ERP layers are at the opposite ends of the Purdue Model, the differences between each layer are significant and not to be overlooked. While HMI and SCADA systems typically operate on a second time scale, MES usually runs at a minute time scale.

Thus, when evaluating ERP vs MES for a given task within your IT infrastructure, consider the time scale for the use-case in question. Do we need to see if we are behind this morning on a critical production order? Are we on track this hour for our productivity goals? How are we doing after the lunch break – on target or half asleep? What are the up-to-the-minute reasons costing us productivity on the plant floor? MES would better suit these needs. Alternatively, do finance teams need to audit bi-monthly resource costs? ERP would better suit this need – auditing minute time scale data would be a nightmare!

So, to help you pick the right tool for the job, consider the time scale that is appropriate for the task. When you do this, you will spare your organization many headaches by selecting the system that delivers the data you need in the time scale required.

Click here to go to Part 2: Context >>>

How Can Sepasoft Help You?

To learn what Sepasoft MES can do for your organization, please schedule a demo.